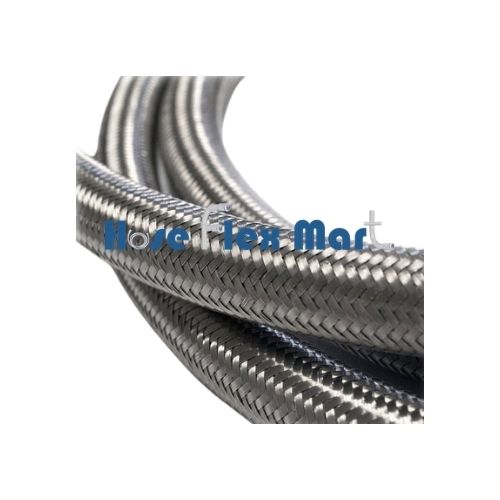

Stainless Steel 304 Corrugated Flexible Hose with SS 304 Braid

Supplier, Manufacturer, Trader & Exporter in Mumbai, Maharashtra, India.

SS 304 Corrugated Flexible Hose with SS 304 Braid, Stainless Steel 304 Corrugated Flexible Hose with Stainless Steel 304 Braid with its chromium-nickel content and low carbon, is the most versatile and widely used of the austenitic stainless steels. Its alloys are all modifications of the 18% chromium, 8% nickel austenitic alloy. SS 304 Corrugated Flexible Hose with Braid proves to be resistant to oxidation, corrosion, and durability. All provide ease of fabrication and cleaning, prevention of product contamination offer a variety of finishes and appearances. SS 304 Corrugated Flexible Hose with Braid are used in corrosion resistant electrical enclosures, auto molding and trim, wheel covers, kitchen equipment, hose clamps, exhaust manifolds, stainless hardware, storage tanks, pressure vessels and piping. Stainless steel 304 Corrugated Flexible Hose with Braid core is generally constructed from grade 304 austenitic stainless steel and formed into annular corrugations. The hose is then braided with either single or double braided option, depending on operating pressures. The braid is constructed using closely woven grade 304 stainless wire.

Characteristics

These are some of its characteristics:

– Forming and welding properties.

– Corrosion/ oxidation resistance thanks to the chromium content

– Deep drawing quality.

– Excellent toughness, even down to cryogenic temperatures which are defined as very low temperatures.

– Low temperature properties responding well to hardening by cold working.

– Ease of cleaning, ease of fabrication, beauty of appearance.

Applications

It is used for a wide variety of home and commercial applications, this is one of the most familiar and most frequently used alloys in the stainless steel family.

- Typical applications include tanks and containers for a large variety of liquids and solids.

- Food industry

- Food processing equipment, particularly in beer brewing, milk processing & wine making.

- For example it is highly suitable and applied in dairy equipment such as milking machines, containers, homogenizers, sterilizers, and storage and hauling tanks, including piping, valves, milk trucks and railroad cars.

- Very common in the brewing industry where it is used in pipelines, yeast pans, fermentation vats, storage and railway cars, etc.

- The citrus and fruit juice industry also uses Type 304 for all their handling, crushing, preparation, storage and hauling equipment.

- Domestic tools industry

- Because of its ability to withstand the corrosive action of various acids found in fruits, meats, milk, and vegetables, Type 304 is used for sinks, tabletops, coffee urns, stoves, refrigerators, milk and cream dispensers, and steam tables. It is also used in numerous other utensils such as cooking appliances, pots, pans, and flatware.

- – Architectural panelling, railings & trim.

- – Chemical containers, including for transport.

- – Heat Exchangers.

- – Woven or welded screens for mining, quarrying & water filtration.

- – Dyeing industry.

- – In the marine environment, because of it slightly higher strength and wear resistance than type 316 it is also used for nuts, bolts, screws, and other fasteners.