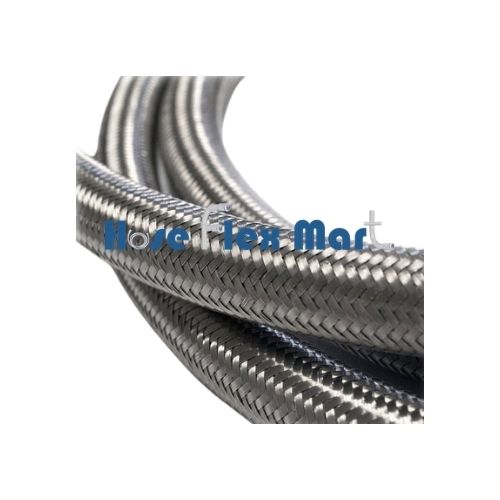

Stainless Steel 321 Corrugated Flexible Hose with Stainless Steel 304 Braid

HoseFlexMart is a Manufacturer of SS 321 Corrugated Flexible Hose with SS304 Braid, Stainless Steel 321 Corrugated Flexible Hose with Stainless Steel 304 Braid, Supplier of SS 321 Corrugated Flexible Hose with SS304 Braid, Stainless Steel 321 Corrugated Flexible Hose with Stainless Steel 304 Braid & Exporter of SS 321 Corrugated Flexible Hose with SS304 Braid, Stainless Steel 321 Corrugated Flexible Hose with Stainless Steel 304 Braid

SS 321 corrugated Flexible Hose with SS 304 Braid, Stainless Steel 321 Corrugated Flexible Hose with Stainless Steel 304 with Stainless Steel 304 braid have a 321 stainless-steel inner hose and a 304 stainless-steel braided cover. 321 stainless steel can withstand very high temperatures. It has high strength, resists scaling, and provides phase stability with resistance to subsequent aqueous corrosion. 304 stainless steel can be sanitized. It can withstand corrosion from most oxidizing acids but is susceptible to corrosion from chloride solutions or from high-saline environments like coastal regions.

SS 321 Corrugated Flexible hoses are ideal for conveying products that need to be heated or cooled during transfer. They are used in asphalt and hot-mix plants and the food, beverage, cosmetic, and pharmaceutical industries. These hoses consist of a flexible inner metal hose enclosed in a flexible metal outer hose. Fittings on the ends of these hoses prevent any material that is being conveyed through the inner or outer hose from moving into the other hose. This allows the inner and outer hoses to be used to convey different materials. For example, steam or hot oils can be circulated through the outer hose to keep viscous material in the inner hose warm and fluid.

Special Hoses Available on Request

Extra High Pressure

Smooth Bore

Jacketed hose Assembly

Application of SS 321 Corrugated Flexible Hose with SS 304 Braid

The main application of Stainless Steel 321Corrugated Flexible Hose with Stainless Steel 304 Braid is where synthetic rubber hoses & plastic hoses do not work well i.e. for hot water, steam, condensate, gas, corrosive liquids, acids, ammonia, carbonic & tartaric acids, tannic acid, nitric acid, sulphuric acid, dye stuff, mercury etc.

In refineries: To convey oils; gasoline, LPG, benzol, petrol, alcohol, LSHS, liquid gases, steam, and other derivates

In Chemical Industry: For the changing, mixing & Conveyer lines

In power Plants: For cooling lines etc.

In Reactor Installation: For cooling lines etc.

In steel Plants: For supply of air and oxygen and for blast furnaces.

And everywhere: Where corrosion and vacuum are major problems.